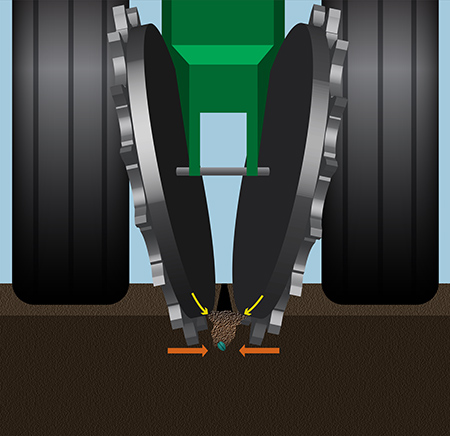

Proper closing wheel adjustment ensures successful seed planting and emergence in agricultural operations. Closing wheels play a vital role in creating the right environment for seeds to germinate and develop into healthy plants. Correct adjustment ensures the soil is firmly packed around the seed, maintaining consistent depth and adequate soil-to-seed contact.

Closing wheels can significantly contribute to reducing seedling emergence issues. Properly closing the seed trench helps create an optimal microenvironment for germination. When adjusted correctly, closing wheels ensure that the seed is securely placed at the desired depth while eliminating air pockets and providing good seed-to-soil contact.

Cast iron closing wheels stand out from other types due to their durability and versatility. Unlike rubber or plastic alternatives, cast-iron closing wheels are heavy and robust, which allows them to exert consistent downward pressure on the soil. This weight aids in firming the soil around the seed trench effectively. Cast iron wheels are less prone to wear and tear, making them a longer-lasting option.

Yes, closing wheel attachments that are compatible with precision planting systems are readily available in the market. These attachments are designed to work seamlessly with precision planting equipment, ensuring precise seed placement and optimal soil closure. They come in various styles and materials to suit different farming practices and soil types.

Closing wheels with depth control adjustments can be a worthwhile investment for farmers seeking precise control over seed depth during planting. These wheels allow farmers to fine-tune the depth at which seeds are planted, accommodating variations in soil conditions and crop requirements.

Generally, you should focus on a series of options by focusing on multiple aspects, such as regularly inspecting for wear and damage, cleaning soil and debris buildup from the wheels, and Lubricating moving parts to prevent friction. Also, you should replace worn or damaged components as needed.

To clean and lubricate closing wheel components, follow these steps:

– Remove the wheels from the planter.

– Use a brush or compressed air to remove soil and debris.

– Inspect for any signs of wear or damage.

– Lubricate moving parts with appropriate grease or lubricant.

– Reassemble the wheels on the planter.

– Regular cleaning and lubrication prevent corrosion, reduce friction, and ensure smooth operation during planting.

Signs that it’s time to replace closing wheels include Excessive wear or damage to the wheel edges, Cracks or fractures in the wheel material, and Reduced performance, such as poor seed-to-soil contact. In addition, it includes Uneven seed placement or emergence issues and an inability to maintain proper adjustment despite regular maintenance.

Replacing worn or damaged closing wheels is essential to maintain planting efficiency and seedling emergence.

Generally, sharpening or repairing damaged closing wheels is not recommended, as doing so may compromise their integrity and effectiveness. Closing wheels are precision components, and attempting to modify or repair them can lead to uneven seed placement and reduced seedling emergence. It’s best to replace damaged or worn wheels with new ones to ensure consistent performance and optimal results during planting.

Discounts and promotions for closing wheels can vary depending on the manufacturer, retailer, and timing. It’s advisable to visit the official website of the closing wheel manufacturer or contact authorized dealers directly. Additionally, you can check for seasonal promotions or special offers from agricultural equipment suppliers.

Most companies provide order-tracking services. You’ll typically need the order number or a tracking number provided by the company to track your order. You can then visit the company’s website or contact our customer support to obtain real-time updates on the status and location of your shipment.

To purchase closing wheels from Closingwheels.com, you should start by visiting the Closingwheels.com website. In addition, you should browse the product catalog to find the closing wheels you need. Once you do that, you add the desired items to your shopping cart and proceed to the checkout page.